Brass Flat Bar

Brass, a metal renowned for its aesthetic appeal and change in character over time, adds to making it a preferred choice in numerous industries. Among its various forms, the brass flat bar stands out for its versatility and wide range of applications. This comprehensive guide will delve into the nuances of brass flat bar, highlighting their uses and distinguishing between the popular alloys C38010 and C38500.

What is it?

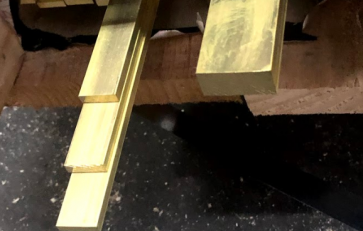

Rectangular strip of brass, known for its flat surface and straight edges. It is typically used in projects with an architectural appeal but also has properties of strength, corrosion resistance, and can have a polished or aged appearance applied. Available in various sizes and thicknesses, brass flat bars are adaptable to different industrial and cosmetic needs.

Uses

Due to its appearance and malleability, brass flat bars are extensively used in:

- Architectural trim and detailing

- Decorative elements in interior design

- Manufacturing of precision instruments

- Furniture and cabinet hardware

- General engineering/electrical components

Alloy C38010 vs C38500: Understanding the Differences

C38010: The Standard Extrusion Alloy Alloy C38010, is a widely used brass alloy for extrusions. This leaded alpha/beta brass alloy is noted for its ease of extrudability and bright golden appearance, a result of a small aluminium addition.

Key Characteristics of C38010:

- Can be machined but not ideal

- High corrosion resistance

- Ideal for applications requiring minimal cold working

- Predominantly used in extruded shapes such as angles, flats, and profiles under 9.53mm thickness

C38500: The Preferred Alloy for Cold Working C38500, often referred to as Architectural Bronze, is another popular brass alloy. Unlike C38010, this alloy is more suited for applications involving significant cold working.

Distinct Features of C38500:

- Ideal for machining due to a small lead content

- Enhanced resistance to corrosion and wear

- Predominately used in applications where thickness is equal to 9.53mm or greater

- Generally, supply in flat, rectangle or square sections only

Comparing C38010 and C38500 While both C38010 and C38500 are excellent choices for brass flat bars, their specific properties make them suitable for different applications. In generally from the same manufacturer there is visually limited to no difference in appearance. Some caveats to the above to consider

- From the same manufacturer

- Manufactured with the same method, e.g. drawn, extruded or continuous cast

- are supplied from the same batches

- stored in the same conditions (material can age overtime in humid conditions even in storage)

Why Choose Brass Flat Bars? Opting for brass flat bars in projects comes with several advantages:

- Aesthetic Appeal: The natural golden hue of brass adds elegance to any application.

- Durability: Brass is known for its long-lasting nature, resisting corrosion and wear over time.

- Machinability: Both C38010 and C38500 alloys are easy to machine, allowing for precision in manufacturing.

- Versatility: Suitable for a wide range of applications, from decorative to structural.

- Dynamic Appearance: artificial or natural aging can occur to this material to result in differences in colour and texture over time

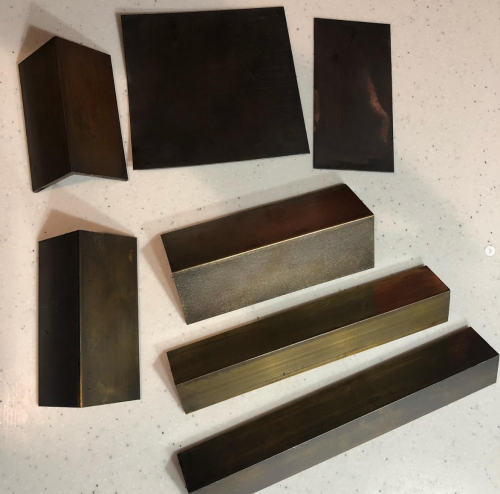

Finish?

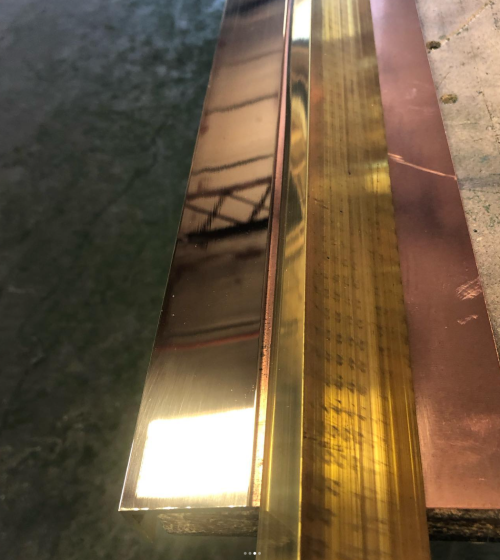

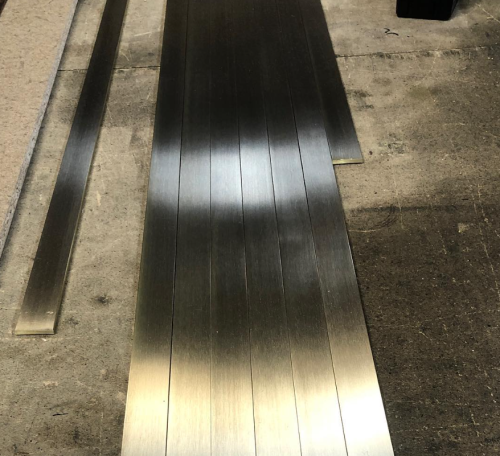

These materials come in a standard “Extruded” finish as pictured, they can also have a brushed finish, polished finish or aged finish. Australian Metals can complete brushed finishes in house and can suggest business partners to complete alternative finishes

- polished brass

- brushed brass

- brass flat bars

- aged brass

Below is a list sizes we generally stock but aren’t limited to, C38010 is a standard grade of brass with good surface finish, C38500 is a free machining brass that can be used for architectural or engineering purposes, the main benefit being this material machines better compared to C38010.

Additional overseas orders can be organised with small minimum order quantities of approximately 150kg. Lead times are approximately 10 weeks.

C38010 / C38500

Please use search function below to find the desired sizes

| Item Code | Alloy | Width | Thickness | Length | Weight (kg) | Quantity | Add to Quote |

|---|---|---|---|---|---|---|---|

| BR380/6.35x3.18x3600 | C38010 | 6.35mm | 3.18mm | 3600mm | 0.7 kg | | |

| BR380/9.53x3.18x3600 | C38010 | 9.53mm | 3.18mm | 3600mm | 1.0 kg | | |

| BR380/12.7x1.59x3600 | C38010 | 12.7mm | 1.59mm | 3600mm | 0.7 kg | | |

| BR380/12.7x3.18x3600 | C38010 | 12.7mm | 3.18mm | 3600mm | 1.3 kg | | |

| BR380/12.7x6.35x3600 | C38010 | 12.7mm | 6.35mm | 3600mm | 2.7 kg | | |

| BR380/15.88x1.59x3600 | C38010 | 15.88mm | 1.59mm | 3600mm | 0.9 kg | | |

| BR380/15.88x3.18x3600 | C38010 | 15.88mm | 3.18mm | 3600mm | 1.7 kg | | |

| BR380/15.88x4.76x3600 | C38010 | 15.88mm | 4.76mm | 3600mm | 2.3 kg | | |

| BR380/15.88x6.35x3600 | C38010 | 15.88mm | 6.35mm | 3600mm | 3.1 kg | | |

| BR380/19.05x1.59x3600 | C38010 | 19.05mm | 1.59mm | 3600mm | 1.0 kg | | |

| BR380/19.05x3.18x3600 | C38010 | 19.05mm | 3.18mm | 3600mm | 1.9 kg | | |

| BR380/19.05x4.76x3600 | C38010 | 19.05mm | 4.76mm | 3600mm | 2.8 kg | | |

| BR380/19.05x6.35x3600 | C38010 | 19.05mm | 6.35mm | 3600mm | 3.7 kg | | |

| BR380/25.4x1.59x3600 | C38010 | 25.4mm | 1.59mm | 3600mm | 1.3 kg | | |

| BR380/25.4x3.18x3600 | C38010 | 25.4mm | 3.18mm | 3600mm | 2.5 kg | | |

| BR380/25.4x4.76x3600 | C38010 | 25.4mm | 4.76mm | 3600mm | 3.7 kg | | |

| BR380/25.4x6.35x3600 | C38010 | 25.4mm | 6.35mm | 3600mm | 5.0 kg | | |

| BR380/31.75x1.59x3600 | C38010 | 31.75mm | 1.59mm | 3600mm | 1.6 kg | | |

| BR380/31.75x3.18x3600 | C38010 | 31.75mm | 3.18mm | 3600mm | 3.1 kg | | |

| BR380/31.75x4.76x3600 | C38010 | 31.75mm | 4.76mm | 3600mm | 4.7 kg | | |

| BR380/31.75x6.35x3600 | C38010 | 31.75mm | 6.35mm | 3600mm | 6.2 kg | | |

| BR385/31.75x12.7x3600 | C38500 | 31.75mm | 12.7mm | 3600mm | 12.3 kg | | |

| BR380/38.1x3.18x3600 | C38010 | 38.1mm | 3.18mm | 3600mm | 3.7 kg | | |

| BR380/38.1x4.76x3600 | C38010 | 38.1mm | 4.76mm | 3600mm | 5.6 kg | | |

| BR380/38.1x6.35x3600 | C38010 | 38.1mm | 6.35mm | 3600mm | 7.4 kg | | |

| BR380/38.1x12.7x3600 | C38010 | 38.1mm | 12.7mm | 3600mm | 14.9 kg | | |

| BR380/50.8x3.18x3600 | C38010 | 50.8mm | 3.18mm | 3600mm | 5.0 kg | | |

| BR380/50.8x6.35x3600 | C38010 | 50.8mm | 6.35mm | 3600mm | 9.9 kg | | |

| BR380/63.5x3.18x3600 | C38010 | 63.5mm | 3.18mm | 3600mm | 6.1 kg | | |

| BR380/63.5x6.35x3600 | C38010 | 63.5mm | 6.35mm | 3600mm | 12.3 kg | | |

| BR380/76.2x3.18x3600 | C38010 | 76.2mm | 3.18mm | 3600mm | 7.4 kg | | |

| BR380/76.2x4.76x3600 | C38010 | 76.2mm | 4.76mm | 3600mm | 11.2 kg | | |

| BR380/101.6x3.18x3600 | C38010 | 101.6mm | 3.18mm | 3600mm | 10.0 kg | | |

| BR380/101.6x6.35x3600 | C38010 | 101.6mm | 6.35mm | 3600mm | 19.9 kg | | |

| BR385/19.05x9.53x3600 | C38500 | 19.05mm | 9.53mm | 3600mm | 5.6 kg | | |

| BR385/25.4x12.7x3600 | C38500 | 25.4mm | 12.7mm | 3600mm | 9.9 kg | | |

| BR385/31.75x9.53x3600 | C38500 | 31.75mm | 9.53mm | 3600mm | 9.3 kg | | |

| BR385/38.1x12.7x3600 | C38500 | 38.1mm | 12.7mm | 3600mm | 14.8 kg | | |

| BR385/50.8x9.53x3600 | C38500 | 50.8mm | 9.53mm | 3600mm | 14.8 kg | | |

| BR385/50.8x12.7x3600 | C38500 | 50.8mm | 12.7mm | 3600mm | 19.7kg | | |

| BR385/76.2x9.53x3600 | C38500 | 76.2mm | 9.53mm | 3600mm | 22.2 kg | | |

| BR385/101.6x9.53x3600 | C38500 | 101.6mm | 9.53mm | 3600mm | 29.6 kg | | |

| BR385/152.4x12.7x3600 | C38500 | 152.4mm | 12.7mm | 3600mm | 59.1 kg | | |

| BR380/9.53x4.76x3600 | C38010 | 9.53mm | 4.76mm | 3600mm | 1.4 kg | | |

| BR385/152.4x12.7x3600 | C38500 | 152.4mm | 9.53mm | 3600mm | 44.8 kg | | |

| BR380/152.4x6.35x3600 | C38010 | 152.4mm | 6.35mm | 3600mm | 29.8 kg | |